Instrumentation

FLOWMETERS

Vortex Flow Meter

A vortex flow meter is a flow measurement device best suited for flow measurements where the introduction of moving parts presents problems. They are available in industrial grade, brass or all plastic construction. Sensitivity to variations in the process conditions are low and with no moving parts have relatively low wear compared to other types of flow meters.

Electromagnetic

Electromagnetic flow meters (Liquid Flow Meter, Water Flow Meter, irrigation Flow Meter ) are widely used for flow measurement of conducting fluids. It Works on the Faraday’s law of Electromagnetic Induction. The new sensors are more compact in size & more sensitive. Earth ring or Earth electrode both option are available. Empty tube detection is also provided. Transmitter comply with IP67 & Sensor comply with IP68.

EM Compatibility :

As per IEC 61326-2-3 &

IEC 61000-3-2; 2006

Thermal Mass

Thermal mass is the ability of a material to absorb and store heat energy. A lot of heat energy is required to change the temperature of high density materials like concrete, bricks and tiles. They are therefore said to have high thermal mass. Lightweight materials such as timber have low thermal mass. Appropriate use of thermal mass throughout your home can make a big difference to comfort and heating and cooling bills.

Coriolis

The basic operation of Coriolis flow meters is based on the principles of motion mechanics. As fluid moves through a vibrating tube it is forced to accelerate as it moves toward the point of peak-amplitude vibration. Conversely, decelerating fluid moves away from the point of peak amplitude as it exits the tube. The result is a twisting reaction of the flow tube during flowing conditions as it traverses each vibration cycle.

Ultrasonic

Intelligent meters for custody transfer and fiscal oil and gas measurement that deliver advanced diagnostics for unparalleled accuracy and reliability.

ANALYSIS (LIQUID & GAS)

pH, Conductivity, Turbidity, Dissolved O2, Chlorine, Gas Analyser (O2, CO, CO2, NOx, SO2, He, Ar, H2, CH4, HCl, NH3)

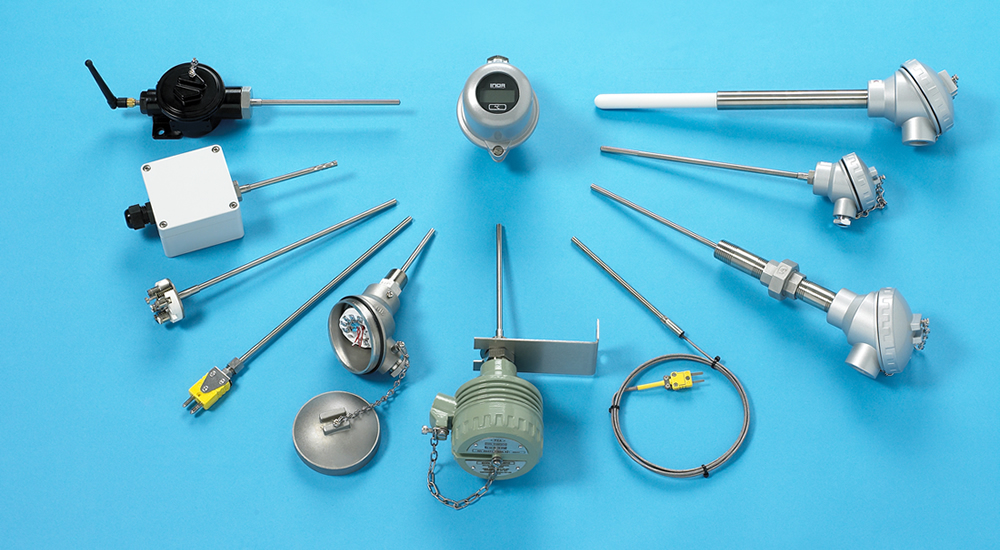

TEMPERATURE

RTD/ Thermocouples: We are offering wide range of RTD for general purpose to demanding Application these are available in 2 wire or 3 wire Configuration, the variety of sheathing makes it suitable for most critical applications.

Transmitters: We are offering wide range of Loop Powered Indicator with Temperature Sensors designed for general purpose applications. These are available in 2 wire or 3 wire Configuration, the variety of sheathing makes it suitable for most critical applications. The Plug-on display fits for the 4~20mA 2-wire technique, 16-bit ADC MCU inside, allows users to use the two buttons, to program the zero point, span, decimal point, damping and alarm point etc.

Indicator:Indicators are high performance instruments used for monitoring analogue signals in the vast majority of industrial and laboratory processes.

Controllers: Controller is a Microprocessor based Digital Process Controller, which can be applied to high-precision measurement and control of temperature, pressure, discharge, liquid level and humidity etc

LEVEL (TRANSMITTERS & SWITCHES)

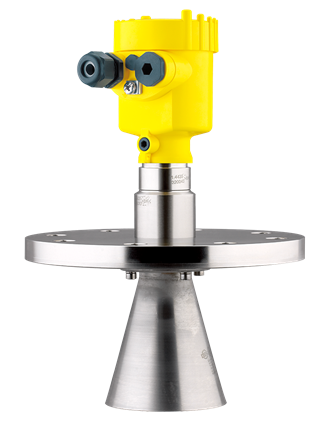

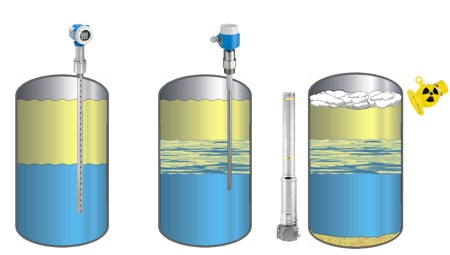

Non-Contact Radar:

The Non-Contact Radar is a “downward-looking” measuring system, operating based on the time-of-flight method. It measures the distance from the reference point (process connection) to the product surface. Radar impulses are emitted by an antenna, reflected off the product surface and received again by the radar system.

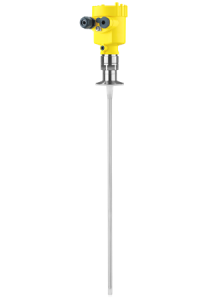

Guided Wave Radar:

The Guided Wave Radar Level measuring instrument is a “downward-looking” measuring system that functions according to the ToF method (ToF = Time of Flight). The distance from the reference point (process connection of the measuring device see page 44) to the product surface is measured. High-frequency pulses are injected to a probe and led along the probe. The pulses are reflected by the product surface, received by the electronic evaluation unit and converted into level information. This method is also known as TDR (Time Domain Reflectometry).

Ultrasonic:

The sensor of the system transmits ultrasonic pulses in the direction of the product surface. There, they are reflected back and received by the sensor. The instrument measures the time t between pulse transmission and reception. The instrument uses the time t (and the velocity of sound c) to calculate the distance D between the sensor membrane and the product surface

Electromechanical:

Devices which carry out electrical operations by using moving parts are known as electromechanical. Strictly speaking, a manually operated switch is an electromechanical component, but the term is usually understood to refer to devices which involve an electrical signal to create mechanical movement, or mechanical movement to create an electric signal.

Nucleonic:

The Gammapilot compact transmitter is made for non-contact point level detection, continuous level, interface and density measurement in liquids, solids, suspensions or sludges. The variable transmitter concept with NaJ crystal or plastic scintillators in different lengths guarantees optimum adaptation to individual applications. The transmitter contains a scintillator, photomultiplier and evaluation unit.

Capacitive:

The principle of capacitance level measurement is based on the change in capacitance of the capacitor due to the change in the level. The probe and container wall (conductive material) form an electric capacitor. When the probe is in air m, a certain low initial capacitance is measured. When the container is filled, the capacitance increases the more the probe is covered n, o. As of a conductivity of 100 μs/cm, the measurement is independent of the value for the dielectric constant (DK) of the liquid. As a result, fluctuations in the DK value do not affect the measured value display. Furthermore, the system also prevents the effect of medium build-up or condensate near the process connection for probes with an inactive length.

Hydrostatic:

The ceramic measuring cell is a dry measuring cell, i.e. pressure acts directly on the robust ceramic process isolating diaphragm of the hydrostatic level sensor. Any changes in the air pressure are routed through the extension cable, via a pressure compensation tube, to the rear of the ceramic process isolating diaphragm and compensated for. A pressure-dependent change in capacitance caused by the movement of the process isolating diaphragm is measured at the electrodes of the ceramic carrier. The electronics convert the movement into a pressure-proportional signal which is linear to the medium level.